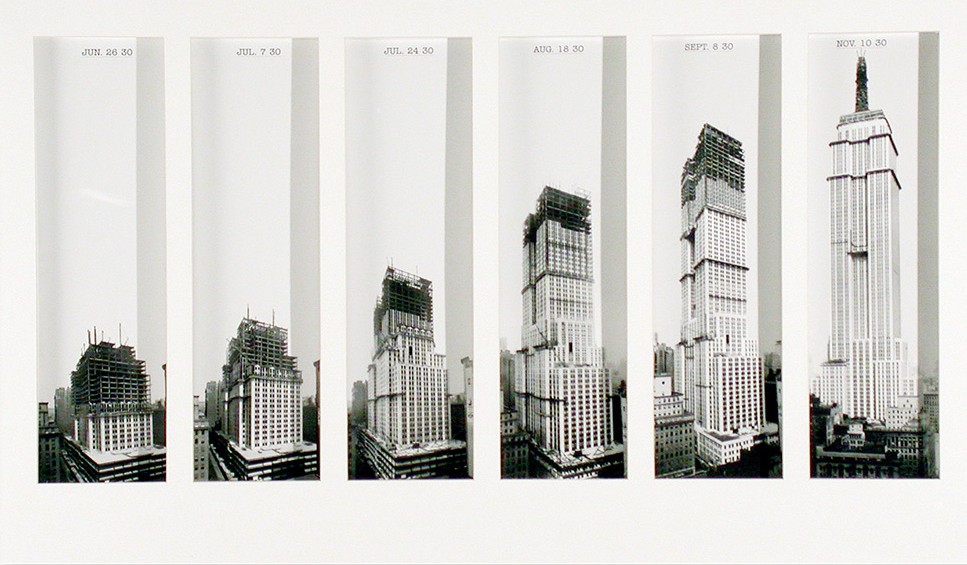

In complete contrast to the previous post on the Sydney Opera House, The Empire State Building stands as one of the best examples of good project management of the last century. Conceived by one of GM’s lead executives, John Raskob. The project’s purpose was simple – to be taller than the Chrysler building and to be completed prior to the Chrysler Building. This was a “Race into the Sky”. Originally it was aggressively estimated the project would take 422 days to build at a cost of $60m (incl. demo & foundations) using traditional methods of construction.

Demolition started 28 days prior to the wall street crash & ultimately the great depression of the 1930’s. Raskob refused to back out

During the contractor interview process, the successful contractors, Starrett Brothers & Eken, offered a highly innovative approach. Instead of claiming they owned everything that was needed to build the building, they actually boldly stated that they had nothing of use & would completely innovate & custom make all building equipment specially for the project, as traditional equipment was prohibitive to the programme & budget on such an extreme undertaking. The client committee agreed & they were awarded the project.

Immediately they began to work collaboratively with the experienced architects, Shreve, Lamb & Harmon Associates as well as the other stakeholders in a detailed planning exercise that would brainstorm and problem solve all critical elements. During this process, the team decided on fast-tracking the commencement by staging the design & commencing prior to complete design completion. This was a highly innovative approach at the time & required a detailed understanding of the critical elements of each scope.

The Builders developed new and highly efficient modes of construction. Bricks were mechanically dumped in 2 identical purpose built hoppers that connected to custom brick railways and lifts. Not only were the streets not closed for unloading but the bricks were not handled until they needed to be placed – saving the labour of 38 men per day! Every piece of steel was marked, numbered and loaded in the correct erection order meaning they could be placed straight into position. Most elements were fixed in place within 80hrs of coming out of the furnace. 5 fast food restaurants were established on the 3rd, 9th, 24th, 47th & 64th floors resulting in only 15% of workers leaving the site over lunch & an estimated 20min additional productivity every day as the workers did not choke the lifts at lunch. Gantt charts were employed and monitored – a relatively new science that the armed forced had been using for 7-8 years, but not common in construction. This assisted the assembly of trades to follow seamlessly. Furthermore, Starrett Brothers & Eken only used the best trades at excellent rates for all workers.

On April 11, 1931, the building was completed. In a twist of fate, the great depression had helped to provide a steady supply of labour (nearly 3500 at peak) to meet the programme & it was completed 12 days prior to the estimate. Costs came in under budget, with the total cost of just under $41m. Although originally a $60m budget, the depression & associated value of the USD, as well as the revised construction methodologies, resulted in the revised detailed estimate was reduced to $42m at foundation time. Only 14 workers died during the construction – a strong result at the time.

So why was the Empire State Building such a success?

· Firstly, there was such a clear and simple project brief – build the tallest building in the world & complete it before the other rivals under development.

· Next, all involved were experts in their fields. Shreve, Lamb & Harmon Associates were experts in high rise towers as were Starrett Brothers & Eken.

· In terms of contractors, the principal builder was engaged what in modern terms would be considered a construction management arrangement. Effectively, Starrett Brothers & Eken had a fixed fee of $500k, with all contractors & materials individually engaged & purchased separately. With all trades approved separately, experts and good contractors were engaged not the cheapest available as often is the case in modern fully fixed price work. The team of contractors got the job done.

· Good planning and Gantt chart management was critical as there was no space to store and no time to double handle.

· Finally & most importantly, with the early involvement of the builders & common goals for all major parties, the most collaborative environment was created throughout, in particular the early design phase of the project.

To close out this post, here are 2 insightful quotes regarding the importance of open collaboration & having common goals. One from the architect, one from the builder:

o “Problems must be dealt with through authority greater than the architect possesses” to avoid “a duplication of effort and a loss of time too expensive to be tolerated.”

The Architect - R.H. Shreve “The Empire State Building Organization,” Architectural Forum 52 (1930)

o “I doubt that there was ever a more harmonious combination than that which existed between owners, architects, and builder. We were in constant consultation with both of the others; all details of the building were gone over in advance and decided upon before incorporation in the plans.”

The Builder - Paul Starrett, Changing the Skyline: An Autobiography (New York: McGraw Hill, 1938)

Documentary - https://www.youtube.com/watch?v=JrrO_luMvcA